1/3ページ

ダウンロード(2.7Mb)

IPG D33 2Dハイパワースキャナーは、業界をリードするリモートレーザ溶接ソリューションで、最大12 kWのCW(連続波)出力を扱えます。これにより、より大きな溶接溶込みと移動速度の向上が可能になり、生産性の向上とコストの削減につながります。

さまざまな光学系の組合せと、あらゆるシリーズのIPGレーザ(YLS、YLS-AMB、YLR、YLPN)とのインターフェース機能を提供することで、ユーザー様は装置を簡単にプロセスに合わせることができます。スキャナーとレーザ間のIPGカスタマイズインターフェースは、容易な統合と完全なプロセス制御を可能にします。さらに、スキャナ統合センターは、自動化システムにシームレスに統合するために必要なすべての接続をユーザーに提供します。

このカタログについて

| ドキュメント名 | IPG D33 2Dハイパワースキャナー |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 2.7Mb |

| 登録カテゴリ | |

| 取り扱い企業 | IPGフォトニクスジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

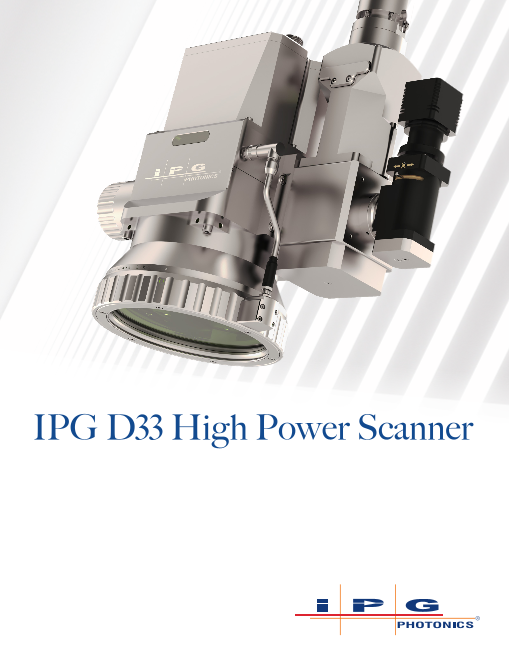

IPG D33 High Power Scanner

Page2

D33 High Power Scanner

IPG D33 2D High-Power Scanners are industry-leading remote laser welding solutions with

up to 12 kW of continuous wave laser power handling that is the highest power handling

capabilities of any scanner in its class. This allows for greater weld penetration and Industrial Connectors

increased travel speeds, which translates to increased productivity and reduced costs. Industrial Design Plug and play architecture

utilizing industrial connectors

Designed for the most rugged

As the world leader in fiber laser technology, IPG understands that no two applications allows for quick installation

environments, 2D High-Power and easy integration

are the same. Offering various optical combinations and the ability to interface with Scanners feature industrial

any series IPG laser (YLS, YLS-AMB, YLR, YLPN), users can easily tailor the equipment IP67 tested enclosures

to the process. The IPG customized interface between the scanner and the laser allows

for easy integration and complete process control. Additionally, the scanner-integration-

center provides users with all the necessary connections for seamless integration into an

automated system.

Welding processes are quickly and easily created with IPGScan software. Manufacturers can

efficiently setup on-the-fly or point-and-shoot processes to optimize product throughput.

Additionally, various interfaces, including Fieldbus (Ethernet/IP, ProfiNet, EtherCAT), are

available to automate the system and provide software and hardware status for complete

control over the process. Contamination

Detection

When combined with the IPG patented LDD process monitoring technology, manufacturers Protect the process

and equipment with

can rest assured that parts coming off of the production line are of the highest possible an integrated sensor

quality. for Protective Window

contamination sensing

IPG D33 2D High-Power Scanners provide tailored solutions, easy integration, and

powerful programming functionality, with reduced overall costs.

Quick Exchange

Window Assembly

IPGScan Software Reduce production down-time for

Protective Window change-out

thanks to the quick exchange

Window Assembly design

NO

SOFTWARE Eliminate excessive license and renewal fees with IPGScan remote scanning

LICENSES software, which is available for download at any time.

CONFIGURE REMOTE LASER

WELDING APPLICATIONS IN MINUTES IPGScan Process & Timing Visualization

PROCESS By importing STL models, users can create realistic process simulations in

VISUALIZATION IPGScan. This functionality allows users to develop precise process timings IPGScan is a powerful software suite that provides users with process parameters specifically tailored to the application

and ensure beam angles will not clip expensive fixturing. and laser being utilized. Within IPGScan, users have the ability to import CAD models, place process objects (e.g.

welds), create simulated motion paths, and optimize process timings using advanced timeline functionality.

ON-THE-FLY Advanced timeline functionality allows users to reduce process cycle time by Graphical display of the laser beam emitting from the scan head helps to ensure that expensive fixturing will not be

LASER WELDING providing detailed process timings & easy to use tools for making process clipped by the beam. These powerful features enable users to visualize the complete process before equipment ever hits

parameter changes. the shop floor. When equipment is set up, users can easily transition from programming in the offline world to the

real world with a few quick calibrations. Loaded with powerful software features, IPGScan allows users to develop

complete process solutions while reducing overall costs.

Page3

Specifications

Compatible Laser Series YLS, YLS-AMB, YLR, YLPN

Max Multi-Mode CW Power (kW) 12.0

Max Single-Mode CW Power (kW) 4.0

Available Fiber Adapters HLC-8, HLC-8 with Rotary, HLC-16, LCA

Optical Specifications

Wavelength (nm) 1065 – 1075

Clear Aperture (mm) 33

Focus Lens Name F254 MM F405 SM F413 MM F510 MM F500 SM F505 SM

Focal Length (mm) 254 405 413 510 500 505

Nominal Working Distance (mm) 261 510 415 530 608 635

Square Field Size ([X]mm x [Y]mm) 1 110 x 110 200 x 200 200 x 200 250 x 250 250 x 250 270 x 270

Galvo Long-Term Drift (µm)2 <30 <50 <50 <60 <60 <60

Galvo Positioning Repeatability (µm)3 <8 <12 <12 <15 <15 <15

Collimator Options (mm) 100, 120, 140, 150, 160, 180, 200

Mechanical Specifications

IP Rating IP67

Scanner Dimensions [LxWxH] (mm)4 317 × 190 × 357

Scanner Weight (kg)4 11.3-14.0

Available Accessories

Linear and Circular Air Knife For Spatter and Process Control

Through the Lens Vision Cameras Ethernet, HDMI

Integration Control Center Complete solution containing power supplies, Scanner Fieldbus Interface,

and appropriate cables

External Interfaces for Automated Systems Integration

Scanner Fieldbus Interface Supported Protocols: Ethernet/IP, ProfiNet, EtherCAT

Extended IO Discrete IO Interface: 19 Digital Inputs, 16 Digital Outputs

Motion Interface For motor control or encoder feedback

Capable of single-ended or differential signal feedback

1. Rectangular fields of view are available for some lens configurations

2. Long-term drift with constant ambient conditions after the readiness for operation (heat-up time). Both galvos considered

3. Both galvos considered

4. Assuming 2D High Power Scanner with 510 mm focal length, 120 mm collimator, LCA fiber adapter, and without LDD, camera, or air knife attachments

+1 (508) 373-1100; LASER RADIATION

DO NOT STARE DIRECTLY INTO THE BEAM

IPGPhotonics.com/contact OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

MAX. AVERAGE POWER: 1mW

www.ipgphotonics.com WAVELENGTH RANGE: 600-700nm

IEC 60825-1:2014

Legal notices: All product information is believed to be accurate and is subject to change without

notice. Information contained herein shall legally bind IPG only if it is specifically incorporated into

the terms and conditions of a sales agreement. Some specific combinations of options may not be

available. The user assumes all risks and liability whatsoever in connection with use of a product or its

application. IPG, IPG Photonics, The Power to Transform and IPG Photonics’ logo are trademarks of IPG

Photonics Corporation. © 2024 IPG Photonics Corporation. All rights reserved.