1/12ページ

ダウンロード(1Mb)

オイヒナーのATEX対応安全スイッチの紹介

オイヒナーの電気機械式、及びトランスポンダーコデッド安全スイッチのうち、ATEX対応品を紹介したリーフレットです(日本語リーフレットは準備中です)。

このカタログについて

| ドキュメント名 | オイヒナー 爆発性雰囲気用安全スイッチ |

|---|---|

| ドキュメント種別 | その他 |

| ファイルサイズ | 1Mb |

| 登録カテゴリ | |

| 取り扱い企業 | オイヒナー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

ATEX

Safety switches for potentially explosive atmospheres

1

Page2

ATEX products from EUCHNER

General information

The ATEX directive Prevention of explosions

Since 1 July 2003, all equipment in the EU that is used in a The most effective way of preventing an explosion is to prevent

potentially explosive atmosphere must comply with directive the formation of a potentially explosive atmosphere. This type

94/9/EC. of explosion protection is called primary explosion protec-

This directive is entitled “Equipment for potentially explosive tion. Primary explosion protection is not always possible. For

atmospheres (ATEX)” – ATEX for short. The ATEX directive this reason, ignition of the potentially explosive atmosphere

is intended for manufacturers and users of equipment and must be prevented. This measure

protective systems used in potentially explosive atmospheres. is termed secondary explosion protection. In practice, this

This directive was superseded by directive 2014/34/EU in form of protection is achieved by using explosion protected

April 2016. equipment. This equipment ensures that no ignition source can

be produced due to its operation in a potentially explosive

All previously valid national regulations were standardized in atmosphere.

the course of harmonizing the ATEX directive within the EU

member states. Accordingly, the same, consistent rules for Marking of equipment

explosion protection are applicable here. Equipment intended for potentially explosive atmospheres must

Explosion protection is part of safety engineering and serves to be marked with the symbol.

avoid harm to persons and property damage. The equipment must be marked accordingly on the type label.

Explosion-protection equipment is marked

Prerequisites for an explosion according to:

The following prerequisites must be met for an explosion A pplication

to occur: Equipment properties

A potentially explosive mixture of

– combustible material (gas, vapor, mist or dust)

– oxidizing agents (oxygen)

An ignition source (sparks, hot surfaces, etc.)

Combustible Air (oxygen)

material

Ignition source

2

v

Page3

Marking according to application

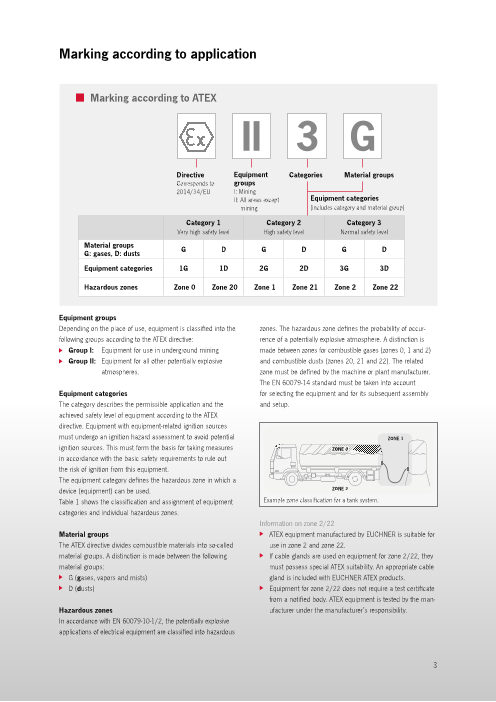

n Marking according to ATEX

II 3 G

Directive Equipment Categories Material groups

Corresponds to groups

2014/34/EU I: Mining

II: A ll areas except Equipment categories

mining (includes category and material group)

Category 1 Category 2 Category 3

Very high safety level High safety level Normal safety level

Material groups

G: gases, D: dusts G D G D G D

Equipment categories 1G 1D 2G 2D 3G 3D

Hazardous zones Zone 0 Zone 20 Zone 1 Zone 21 Zone 2 Zone 22

Equipment groups

Depending on the place of use, equipment is classified into the zones. The hazardous zone defines the probability of occur-

following groups according to the ATEX directive: rence of a potentially explosive atmosphere. A distinction is

Group I: Equipment for use in underground mining made between zones for combustible gases (zones 0, 1 and 2)

Group II: Equipment for all other potentially explosive and combustible dusts (zones 20, 21 and 22). The related

atmospheres. zone must be defined by the machine or plant manufacturer.

The EN 60079-14 standard must be taken into account

Equipment categories for selecting the equipment and for its subsequent assembly

The category describes the permissible application and the and setup.

achieved safety level of equipment according to the ATEX

directive. Equipment with equipment-related ignition sources

must undergo an ignition hazard assessment to avoid potential ZONE 1

ignition sources. This must form the basis for taking measures ZONE 0

in accordance with the basic safety requirements to rule out

the risk of ignition from this equipment.

The equipment category defines the hazardous zone in which a

device (equipment) can be used. ZONE 2

Table 1 shows the classification and assignment of equipment Example zone classification for a tank system.

categories and individual hazardous zones.

Information on zone 2/22

Material groups ATEX equipment manufactured by EUCHNER is suitable for

The ATEX directive divides combustible materials into so-called use in zone 2 and zone 22.

material groups. A distinction is made between the following I f cable glands are used on equipment for zone 2/22, they

material groups: must possess special ATEX suitability. An appropriate cable

G (gases, vapors and mists) gland is included with EUCHNER ATEX products.

D (dusts) Equipment for zone 2/22 does not require a test certificate

from a notified body. ATEX equipment is tested by the man-

Hazardous zones ufacturer under the manufacturer’s responsibility.

In accordance with EN 60079-10-1/2, the potentially explosive

applications of electrical equipment are classified into hazardous

3

v

Page4

Classification and assignment of the equipment categories

Com- Temporary behavior of combustible materials in the Hazardous Equipment marking Equipment

bustible explosion area. zones protection level

materi- Explosive medium: Equip- Equipment (EPL)

als ment category

group

present continuously, for long periods or frequently Zone 0 II

present occasionally Zone 1 II 1G Ga

2G Gb

probably not present. If present, only rarely or briefly Zone 2 II 3G Gc

present continuously, for long periods or frequently Zone 20 II

present occasionally Zone 21 II 1D Da

2D Db

probably not present due to disturbed dust. If present, only

Zone 22 II 3D Dc

rarely/briefly

Table 1

Hazardous zones Equipment categories

Zone 0 C ategory 1G/1D

Area in which a potentially explosive atmosphere comprising Equipment in this category is intended for use in areas in which

a mixture of air and combustible gases, vapors or a potentially explosive atmosphere comprising gases (G) or dusts

mists is present continuously, for long periods or (D) is present continuously, for long periods or frequently.

frequently. Requirements for the equipment

Zone 20 Very high level of safety. The equipment remains protected

Area in which a potentially explosive atmosphere comprising a against providing a source of ignition even in case of malfunc-

cloud of combustible dust in the air is present continuously, tions to be expected only rarely. The equipment also remains

for long periods or frequently. safe if two independent failures occur. Safety is achieved using

two independent means of protection against providing a

source of ignition.

Zone 1 C ategory 2G/2D

Area in which a potentially explosive atmosphere comprising Equipment in this category is intended for use in areas in which it

a mixture of air and combustible gases, vapors or mists can is to be expected that a potentially explosive atmosphere

occasionally form during normal operation. comprising gases (G) or dusts (D) may occur occasionally.

Zone 21 R equirements for the equipment

Area in which a potentially explosive atmosphere comprising High level of safety. The equipment remains protected against

a cloud of combustible dust in the air can occasionally form providing a source of ignition even in the case of malfunctions or

during normal operation. fault conditions to be expected frequently. Safety is achieved using

one means of protection against providing a source of ignition.

Zone 2 C ategory 3G/3D

Area in which a potentially explosive atmosphere comprising Equipment in this category is intended for use in areas in which it

a mixture of air and combustible gases, vapors or mists is not to be expected that a potentially explosive atmosphere may

usually does not form or forms only briefly during occur due to gases (G) or dusts (D). If a potentially explosive

normal operation. atmosphere nevertheless occurs, then in all probability it will

Zone 22 occur only rarely and for a short period.

Area in which a potentially explosive atmosphere comprising Requirements for the equipment

a cloud of combustible dust in the air usually does not form Equipment offers a normal level of safety. The equipments

or forms only briefly during normal operation. remains protected against providing a source of ignition in

normal operation. ATEX equipment manufactured by

EUCHNER is category 3 equipment.

4

v

Dusts Gases/ vapors /mists

Page5

Marking according to equipment characteristics

n Marking according to standard

Gases Marking for use in atmospheres with combustible gases (zones 0, 1, 2) according to EN 60079-0

Ex nA IIB T5 Gc X

Explosion- Types of protection: Explosion Temperature class: Equipment X:

protected i: Intrinsic safety groups: T1 to T6 protection Special

equipment m: Encapsulation IIA/IIB/IIC Permissible surface level: conditions

o: Oil immersion temperature Ga/Gb/Gc must be met

e: I ncreased safety (e.g. properly

ec: f or equipment tightened cover

protection level Gc screws)

q: Powder filling

p: Pressurization

d: Flameproof enclosure

n: Type of protection

nA: Non-sparking equipment

nR: Restricted breathing

enclosure

Dusts Marking for use in atmospheres with combustible dusts (zones 20, 21, 22) according to EN 60079-0

Ex tc IIIC T90°C Dc X

Explosion- Types of protection: Explosion Maximum surface temperature: Equipment X:

protected i: Intrinsic safety groups: T=Ta+Ti protection Special

equipment m: Encapsulation IIIA/IIIB/IIIC T: Maximum surface temperature level: conditions

t: Protection by Ta: Max. ambient temperature Da/Db/Dc must be met

enclosure Ti: Intrinsic heating of the equipment (e.g. properly

tc: f or equipment tightened cover

protection level Gc screws)

p: Pressurization

5

v

Page6

Types of protection

The general requirements for electrical equipment are listed in type and function, and it is included in the ATEX marking on

the EN 60079-0 standard. Classification occurs into various the type label of the respective device.

types of protection: The type of protection the manufacturer EUCHNER uses the following types of protection (Table 2):

uses for a device (equipment) essentially depends on the device

Basic Marking Type of protection Standard corresponding standard to the type of protection

Type of protection “nR”

Restricted breathing enclosure

Ex nR (zone 2) EN 60079-15

Enclosure designed to restrict the penetration of gas, vapors

and mists

Gases Type of protection “nA”Ex nA (zone 2) EN 60079-15

EN 60079-0 Non-sparking equipment

Type of protection “i”

Ex ic (zone 2) EN 60079-11

Intrinsic safety

Type of protection “ec”

Ex ec (zone 2) EN 60079-7

due to increased safety

Type of protection “t”

Ex tc (zone 22) EN 60079-31

Dusts Protection by enclosure

EN 60079-0 Type of protection “i”

Ex ic (zone 22) EN60079-11

Intrinsic safety

Table 2

Explosion groups

Explosion groups and temperature classes determine the Explosion group IIC includes explosion groups IIB and IIA.

media for which equipment may be used within the hazardous ATEX equipment manufactured by EUCHNER belongs to

zones. explosion group IIB.

Equipment for areas with combustible gases E quipment for areas with combustible dusts

The ignitability of an explosive atmosphere depends on the Material group D is classified into explosion groups IIIA, IIIB

material. and IIIC depending on the size and conductivity of the dust

Gases and vapors are classified into explosion groups IIA, IIB particles (see Table 3).

and IIC depending on the energy required for ignition (see The danger posed by dusts (ignitability) increases from

Table 4 in the chapter on temperature classes). explosion group IIIA to IIIC. ATEX equipment manufactured

by EUCHNER belongs to explosion group IIIC.

The danger posed by the gases (ignitability) increases from ex-

plosion group IIA to IIC. The requirements on the equipment

increase correspondingly. Electrical equipment approved for

IIB, for example, may also be used for explosion group IIA.

Explosion group Dust types

IIIA Combustible fibers and lint (example: textiles)

IIIB

IIIC Non-conductive dust (example: sawdust, flour)

Conductive dust (example: metal dust, dust containing carbon)

Table 3

6

v

Page7

Temperature classes

Electrical equipment is classified into temperature classes T1 A safety clearance (maximum surface temperature to ignition/

to T6. The temperature class relates directly to the smoldering temperature) might also have to be taken into

ignition temperature of gases and dusts (temperature above account.

which an explosive atmosphere ignites) and On equipment intended for use in zones 0, 1, 2 (gases),

s moldering temperature of dusts (temperature above which the related temperature class must be given in the equipment

a deposited dust layer begins to smolder) marking.

and thereby specifies the maximum permissible surface tem- On equipment intended for use in zones 20, 21, 22 (dusts),

perature of the equipment. the maximum surface temperature must be given in the equip-

The maximum surface temperature must always be less than ment marking.

the ignition/smoldering temperature of the explosive atmo-

sphere in which the equipment is used.

Classification of explosive gases according to explosion groups and temperature classes

Ammonia Gasoline Ethyl alcoholMethane Diesel

IIA Cyclohexane AcetaldehydeEthane Fuel oil n-butanePropane n-hexane

IIB

Ethylene glycolTown gas Ethylene

IIC H ydrogen Ethyl etherAcrylonitrile Ethylene oxide

sulfide

C arbon Hydrogen Acetylene Trichlorosilane disulfide

T1 < 450 °C

T2 < 300 °C

T3 < 200 °C

T4 < 135 °C

T5 < 100 °C

T6 < 85 °C

Note: The list contains only some of the explosive materials.

Table 4

Equipment protection level

Devices (equipment) for potentially explosive atmospheres The first letter indicates the type of explosive atmosphere: G for

are classified into protection levels (EPL: Equipment Protection gas and D for dust. The second letter indicates the correspond-

Level). The marking consists of two letters. ing protection level (see Table 1).

7

v

Temperature class Explosion group

Page8

Overview of Electromechanical safety switches

ATEX safety

engineering

Safety switch Safety switch Safety switch Safety switch

NZ1-RS…EX NZ.VZ…EX SGA1…EX STA.A…EX

NZ1-HS…EX

Marking according to

- Application (gases/dusts) II 3 G D II 3 G D II 3 G D II 3 G D

- Equipment characteristics (gases) Ex nR IIB T5 Gc Ex nR IIB T5 Gc Ex nR IIB T5 Gc Ex nR IIB T4 Gc

- Equipment characteristics (dusts) Ex tc IIIC T90° Dc (NZHS)Ex tc IIIC T100° Dc (NZRS) Ex tc IIIC T90° Dc Ex tc IIIC T90° Dc X Ex tc IIIC T110° Dc X

Approvals

- Basic housing accord- - Basic housing accord- - I dentical mounting - Metal actuating head

ing to EN 50041 ing to EN 50041 dimensions to safety - High locking force

Features/specific advantages - W ith impact resistant - With impact resistant switch STA - W ith impact resistant

cover cover - With impact resistant cover

cover

Slow-action switching contacts

Positively driven contacts 1 2 2 3 4 1 2 2 3 4 1 2 2 3 4 1 1 2 2 2 4

NO contacts 1 – 2 1 – 1 – 2 1 – 1 – 2 1 – 1 – – 2 1 –

NC contacts – – – – – – – – – – – – – – – – 1 – – 1 –

Conventional thermal current 4 A 4 A 4 A 1 mA

Switching current, min. (at 24 V) 1 mA 1 mA 1 mA 1 mA

Mechanical life, min. 30 x 106 2 x 106 2 x 106 1 x 106

Housing material Anodized die-cast alloy Anodized die-cast alloy Die-cast alloy Die-cast alloy

Housing dimensions, min. (HxWxD) 128 x 44 x 43.5 mm 142 x 44 x 43.5 mm 123 x 45 x 52 mm 191 x 43 x 46 mm

Ambient temperature -20 to +75 °C -20 to +75 °C -10 to +75 °C -20 to +75 °C

Degree of protection, max., acc. to IEC 60529 IP67 IP67 IP67 IP67

LED indicators – – – –

Depending on actuator

Approach/actuating directions

Approach speed, max. 20 m/min. 20 m/min. 20 m/min. 20 m/min.

Solenoid operating voltage – – – 24 V

Power consumption – – – 8 W

Locking force, max. – – – 3000 N

Cable entry (ATEX cable gland included) M 20 x 1.5 M 20 x 1.5 3 x M 20 x 1.5 3 x M 20 x 1.5

Straight actuator/bent /– / /

Hinged actuator

Door radius, min. 165 mm 200 mm 200 mm

Bolts for safety guards – – –

optionally available p available on request – not applicable

The specified data refer to the respective minimum and/or maximum values for the entire series.

8

Accessories Connection Guard locking Environment Inputs/outputs ATEX

Page9

Overview of Transponder-coded safety switches

ATEX safety Without guard locking With guard locking

engineering

Safety switch Safety switch Safety switch

CES-A-C5…EX CES-C04 CTP…EX

Marking according to

- Application (gases/dusts) II 3 G D II 3 G D II 3 G D

- Equipment characteristics (gases) Ex ic nA IIB T5 Gc X Ex nA IIB T6 Gc X Ex nA IIB T4 Gc X

--Equipment characteristics (dusts) Ex ic tc IIIC T90° Dc X Ex tc IIIC T80° Dc X Ex tc IIIC T110° Dc X

Safety category PL acc. to EN ISO 13849-1 Cat. 4 / PL e Cat. 4 / PL e Cat. 4 / PL e

Approvals

- No own pulsing of the - CES-C04 AP/AR switches - Metal actuating head

safety outputs may be used in potentially - A ttachment compatible with

- External pulsing (possible explosive atmospheres only safety switch STA

with safe PLC, for example) when equipped with housing - With impact resistant cover

Features/specific advantages guard AM-C-C04-Ex-137528 - s eparate pulsing on safety - separate pulsing on safety outputs to detect short

outputs to detect short circuits

circuits

Semiconductor safety outputs 2 2 2

Monitoring outputs (semiconductor) 1 1 2

Switching current per safety output (semiconductor) 100 mA 150 mA 150 mA

Mechanical life, min. – – 1x106

Integrated evaluation unit/ Integrated evaluation unit/ Integrated evaluation unit/

Switch

read head read head read head

Dimensions, min. (HxWxD) 118 x 40 x 40 mm 75 x 30 x 20 mm 245 x 45 x 43 mm

Ambient temperature -20 to +50 °C 0 to +65 °C -20 to +55 °C

Degree of protection, max., according to IEC 60529 IP67 IP67/IP69/IP69K IP65/IP67

LED indicators 2 2 3

Approach directions

Solenoid operating voltage – – 24 DC

Power consumption, max. – – 6 W

Locking force, max. – – 2600 N

Plug connector Plug connector M 12 Plug connector M 8 / connection cable Plug connector M 12

Rectangular actuator (transponder) Typical switch-on distance: Typical switch-on distance: 22 mm 14 mm Straight actuator

Bolts for safety guards – – –

optionally available p available on request – not applicable

The specified data refer to the respective minimum and/or maximum values for the entire series.

9

Accessories Connection Guard locking Environment Inputs/outputs ATEX

Page10

Ordering table

pe 1

) s/

g t

y

f itio

n e s

f 1

) n

n o s o n zo us

ts cl

a

e e

i o

o. c

k ing p

o

ing sit

i

fo

r =d ur ac e

o d /D at rf atu

r

r n d l tor oi tor po bl

e

i i es e

r

n s

u r

m de ar n le n or ta as p x

.

i g m a p

e

Ite Or Gu Mo o m

so M do Su G= T

e m te

Electromechanical safety switches

NZ1RS-3131-M-EX 094169 - - - - - - 2 pos. dr. + 2 NO 2 / 22 T5/100 °C

NZ1HS-3131-M-EX 094167 - - - - - - 2 pos. dr. + 2 NO 2 / 22 T5/90 °C

NZ1VZ-2131E-M-EX 093660 - - - - - - 3 pos. dr. + 1 NO 2 / 22 T5/90 °C

SGA1A-2131A-M-EX 123460 - - - - - - 3 pos. dr. + 1 NO 2 / 22 T5/90 °C

Closed-

2 pos. dr. STA3A-2131A024MF-EX 115584 circuit current 1 NC 2 / 22 T4/110 °C

principle + 1 NO

Open- 2 pos. dr.

STA4A-2131A024MF-EX 115585 circuit current 1 NC 2 / 22 T4/110 °C

principle + 1 NO

Closed-

STA3A-4121A024MF-EX 115586 circuit current 2 pos. dr. 1 NC + 1 NO 2 / 22 T4/110 °C

principle

Open-

STA4A-4121A024MF-EX 123076 circuit current 2 pos. dr. 1 NC + 1 NO 2 / 22 T4/110 °C

principle

Transponder-coded safety switches

Safety switches without guard locking

CES-A-C5H-01-EX 097945 - - - - - - 2 safety outputs 2 / 22 T5/90 °C

(Unicode) (semiconductor)

Actuator:

CES-A-BBA-EX 098158 2 / 22 T6/85 °C

CES-A-BPA-EX 102125 2 / 22 T6/85 °C

CES-C04 any 2 safety outputs 2 / 22 T6/80 °C

(version AP/AR) (semiconductor)

Equipment protection:

AM-C-C04-EX 137528 2 / 22 T6/85 °C

Actuator:

CES-A-BBN-C04-EX 137527 2 / 22 T6/85 °C

Safety switches with guard locking

CTP-L1-AP-U-HA-AZ-SA-EX 136675 Closed- 2 safety outputs 1 monitoring output OD 2 / 22 T4/110 °C

(Unicode) circuit current (semiconductor) (semiconductor)

principle + monitoring output OL

CTP-L1-AP-U-HA-AZ-SA-EX 129512 Closed- 2 safety outputs 1 monitoring output OD 2 / 22 T4/110 °C

(Unicode) circuit current (semiconductor) (semiconductor)

principle + diagnostics

output OI

Actuator (straight):

A-C-H-G-LS-EX 136826 2 / 22 T4/110 °C

1) pos. dr.: positively driven normally closed contact; NC: normally closed contact, NO: normally open contact

10

v

Page11

ss/ Further informationa

e c

l

ce e Details about the various ATEX safety switches and accessories can be found on our homepage at www.euchner.com

atu

r

r r

fa tur

pe . s

u erax p

Te

m

m

a

te

m

11

v

Page12

EN

EUCHNER GmbH + Co. KG

Kohlhammerstraße 16

70771 Leinfelden-Echterdingen

Germany

Tel. +49 711 7597-0

Fax +49 711 753316

info@euchner.de

www.euchner.com

136805-03-04/17 Subject to technical modifications; no responsibility is accepted for the accuracy of this information. © EUCHNER GmbH + Co. KG · TA